Automation solution for Parison Control in Blow molding machines :

Automation Package (PLC system attachment) for Blow molding machines in Plastic industry and Parison controller. |

|

| Upgradation of the PLC system from old control system to latest Allen Bradley or Siemens PLC system with Graphic Operator Panel of 10” or 12” Color Touchscreen HMI. |

|

|

| Retrofitt automation solution for Blow molding machine. |

|

|

| Conversion of existing old Parison Controller to latest PLC based Parison Controller comprising of latest Allen Bradley or Siemens PLC system and Graphic User Interface of 10” / 12” Touchscreen HMI. |

|

|

| SCADA software solution for Centralized Monitoring of all Ring frame machines and Shift wise / daily Reports for the Production data management. |

|

Customers Feedback :

|

Tainwala Polly containers Ltd. - Blow Molding Machine Automation : Automation of Blow Molding Machine with Thickness (Parison) Control using Allen Bradley MicroLogix 1200 series PLC and Hi-Tech & Delta Touch screen graphic display. 02 nos. of Projects executed. |

|

|

| BloKraft Engineers, Vapi : Automation of Thickness Control (Parisian Control) System for Blow Molding Machine using Allen Bradley Micrologix 1200 PLC and Hi-Tech 4.7” Touch Screen MMI. 04 nos. of Projects executed

. |

|

|

Bombay Chemicals, Thane

Blow Molding Machine Automation : Automation of Blow Molding Machine with Thickness (Parison) Control using Allen Bradley MicroLogix 1500 series PLC and Proface 12.5” Touch screen graphic display. With Control Panel. |

|

|

Maldar Barrels, Taloja - Blow Molding Machine Automation : Automation of Blow Molding Machine with Thickness (Parison) Control using Allen Bradley MicroLogix 1500 series PLC and Proface 12.5” Touch screen graphic display. With Control Panel. |

|

Problem facing with OLD system :

- Old Parison controller without PLC system

- Parison control not satisfactory

- OEM HMI which is out dated.

- No support from OEM

- Trouble shooting was difficult.

- Frequent Breakdown of Machine.

- Spare cost was very high.

|

|

Advantages with Pyramid Automation’s Parison Controller :

- Proven and Satisfactory Parison Control

- User friendly PLC & HMI system

- Easy Troubleshooting

- Low cost.

- Easy availability of spare and system.

- Minimize breakdown.

- Increased productivity.

|

SCADA software solution for Centralized Monitoring of all 10 nos. of Marzoli RingFrames and Shift wise / daily Reports for the Production data management. |

Complete solutions for blow molding applications :

Pyramid Automation offers turnkey system solutions for the blow molding industry that offers automation solution for controlling blow molding processes with reduced functionality. Fast and precise wall thickness control and fast control of the Extruder & clamping units are key factors for ensuring product quality in the blow molding process.

The blow molding controller, designed by Pyramid Automation specifi cally for blow molding machines offers excellent features functions

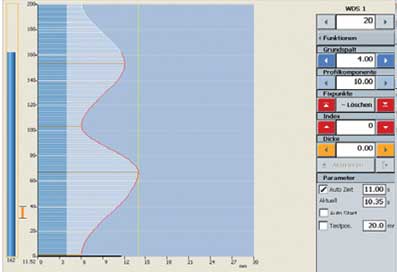

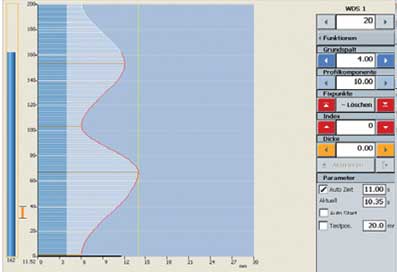

The main operating screen of the blow molding controller is the wall thickness editor.

Wall thickness control :

- wall thickness curve with up to 400 interpolation points.

- display of the accumulator level.

- display of the current parison length.

display of the current curve.

Temperature controller :

- Independent PID Temperature Controller or PLC based PID Control.

- Actual and Historical Trends.

- Bar chart display of set value/actual value and tolerances.

- display of heating/cooling.

- heating and cooling systems with separately adjustable pulse width modulation.

- automatic parameter identifi cation, separately for heating and cooling loop.

- thermocouple monitoring (open, shortcircuit, voltage reversal).

- heating current monitoring (open, shortcircuit, leakage current).

Blow molding is the process of manufacturing hollow containers like Bottles, Jerry cans, Jars, Drums, tanks etc. from plastics. The most common blow moulded plastic resins are HDPE, LDPE, PVC, PET, PP etc. The basic process is to heat up the raw material to a molten state and blowing to the shape of cavity of the mould by air pressure. The blowing of air made the process known as blow molding.

Parison Thickness Control : Parison control means dynamically controlling thickness of Parison to get a uniform thickness container on an Extrusion Blow Moulding machine. It helps to maintain the required thickness axially and radially on the product made out of Extrusion Blow Moulding (EBM).

What is Parison? : It is the molten tubular form made on an Extrusion Blow Molding machine by extruding thermo plastic resins. This viscous melt resin called Parison is put into two halves of Blow Molds and shaped to the form of cavity of mould by blowing compressed air.

Why control required? : When the Parison comes out of the die head of the EBM machine it will be in the molten state. Due to the self-weight the Parison will elongate resulting in a thinner top portion compared to the bottom portion. This will cause uneven thickness in the article made. Also the complex geometries of the product to be molded necessitate varying the parison thickness to get more uniform product wall thickness.

The advantages : Uniform article wall thickness and hence improved quality due to lesser thermal stresses during processing.

· Even distribution of thickness and hence possibility for reduction in weight.

· Reduction in top and bottom wastage and hence higher production.

· Reduced cooling time due to uniformity of thickness and hence higher production.

Different types of Parison Control : Closed loop control (Multi-point Parison Programmer)

Closed loop electro-hydraulic control system can be fitted on the machine to control the parison thickness at several points (30 times or 100 times or more). Since this is a closed loop system the accuracy is much better than ordinary system and the resulting container will have most uniform thickness.

Axial Wall thickness Control : All the above described systems are for thickness control in axial direction of Parison. This is the most common Parison controls.

Radial Wall thickness Control (PWDS) : Other than the axial wall thickness control, for some specific and complex products, thickness control in radial direction is required. This is achieved by transforming the uniform annular space through which parison comes out to elliptical shape.

Time based and position based Control : In the continuous extrusion blow moulding time based systems are used. That is the parison thickness is controlled on a definite interval of time. Here the total time for one parison cycle is divided by the number of points to calculate the time interval.

In accumulator type extrusion blow moulding either a time based or a position-based system can be used.

In position based system a potentiometer senses the position of the push out (accumulator) cylinder stroke and programs the profile points with respect to the position.

In time based system the profile points are programmed with respect to the time taken for parison push out.

To overcome the variations in time the controller automatically updates the time in each cycle and uses it for programming the next cycle.